A world first for Algentech, a specialist in cutting-edge genome-editing technologies and synthesis tools. Its technology enables the production of proteins and nucleic acids in plant chloroplasts. A quantum leap for many industrial sectors seeking new biosourced production routes.

Yesterday, the journal Nature Plants published the process patented by Algentech. The article describes for the first time in the world an autonomous expression system in the form of minichromosomes that have the ability to self-replicate in chloroplasts. The method does not require integration of the genes of interest into the chloroplast genome. It therefore generates a nucleic acid and protein expression level 5 to 10 times higher than in the case of insertion.

Plants and algae transformed into green factories

In addition to a very high production yield, up to 70 % of total soluble proteins, the system offers the possibility of transferring biosynthetic pathways in their entirety: where existing technologies are limited to the integration of a few genes, Algentech's tool achieves the performance of simultaneous expression of 15 to 20 genes in plant cells. This technological leap forward makes it the tool of choice for synthetic biology and green chemistry applications in a wide range of sectors, including the production of peptides, nucleic acids, enzymes, therapeutic compounds and other molecules of interest to the pharmaceutical, cosmetics, food and energy industries...

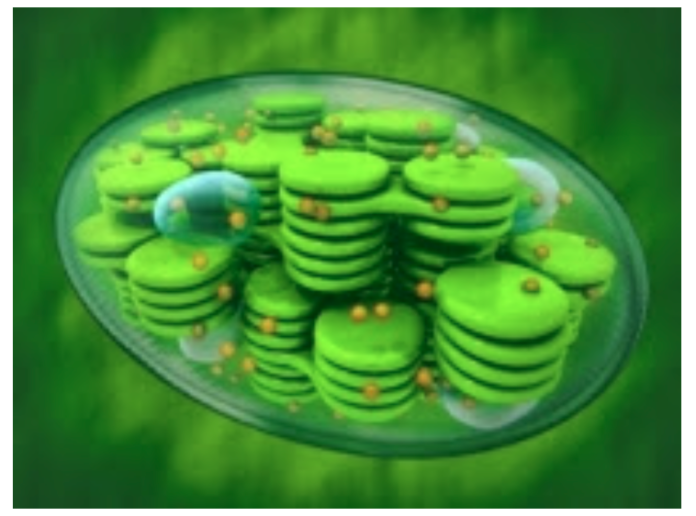

Based on chloroplasts, the organelles responsible for photosynthesis in plant cells, Algentech's proprietary technology is comparable to biological production systems in microorganisms, but with a notable advantage: using sunlight as an energy source while consuming carbon dioxide (CO2). Plants are thus transformed into veritable green production factories, sustainable and respectful of the environment. Tested in tobacco, soya, carrots and duckweed, the system is transferable to a wide range of terrestrial plant species, and potentially also to photosynthetic algae, which have chloroplasts at the heart of their cells.

Algentech, a bioproduction player open to industrial partnerships

Awarded the Genopole® label and supported by Bpifrance, the company has entered into industrial and academic partnerships. Its platform will be used to produce natural biopesticide molecules for the agrochemical industry and enzymes for the biofuels sector. It is open to new collaborations to extend the scope of applications and increase production capacity. For example, the technology is promising for the biological production of squalene, useful in the cosmetics industry and as a vaccine adjuvant, or enzymes involved in the production of biohydrogen, a renewable energy source contributing to the energy transition.

"This technological breakthrough enables Algentech to position itself as a biomanufacturing player in France at a time when Europe's industrial production policy, which showed its shortcomings during the Covid pandemic, is changing, says Isabelle Malcuit, General Manager and Scientific Director. It responds to the need to strengthen and diversify industrial capacities at national level in a sustainable and environmentally-friendly way".