Finnish deeptech company ColloidTek (Collo) has developed Collo Analyzer, an innovative real-time quality control system for industrial liquid processes.

Unlike traditional laboratory analysis methods, Collo Analyzer enables instant on-site analysis of liquid quality.

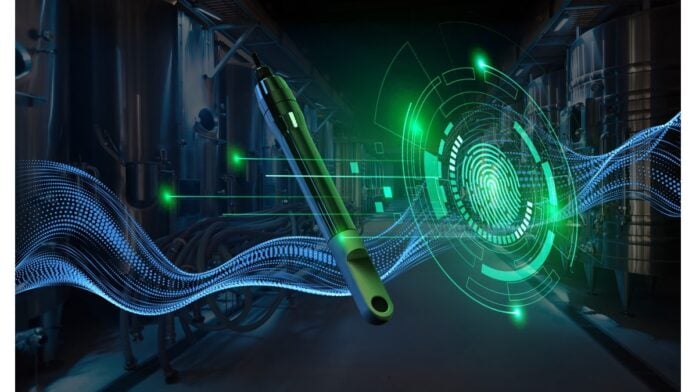

"Collo creates a "liquid fingerprint" of the liquid being analyzed based on its dielectric properties. Each liquid fingerprint is unique, enabling Collo to detect not only individual products, but also minute variations in the analyzed liquid. Thanks to continuous analysis and instantaneous results, Collo can gauge the quality of the liquid at any time".explains Matti Järveläinen, CEO of Collo.

All it takes is two seconds. The measurement is taken manually on site by dipping the detector into the product, directly on the production line. There's no need to send samples elsewhere; results are available instantly. This is thanks to the EMF (ElectroMagnetic Field) technology and advanced algorithms on which Collo's solution is based.

"The fingerprint of a liquid is compared with the criteria required by the customer. If anything differs from these criteria, the customer knows immediately and can take appropriate action. This solution reduces the risk of dangerous errors and poor-quality batches, explains Matti Järveläinen. Our ultimate goal is to provide companies with a cost-effective tool capable of enabling them to maintain rigorous quality control over their liquid transformation processes."

Simplified quality control

Most systems currently available can only analyze liquids with specific viscosity, transparency or other properties. This often means having different analysis systems and detectors at each test point. A complex system with multiple detectors, which is difficult to use and yet does not guarantee effective quality control, becomes necessary.

Collo Analyzer can be used with thick, transparent or non-conductive liquids. A single sensor is all it takes to measure the quality of all the liquids present in the transformation process.

According to Collo, this solution is able to detect multiple risks or deviations simultaneously. It streamlines complex quality control processes, replacing other tests and covering aspects of safety and quality ignored by other systems. This technology not only speeds up the quality control process, but also enables manufacturers to take immediate corrective action when deviations are detected. This reduces the risk of costly recalls, and enables manufacturers to ensure that every batch of product meets the most stringent quality and safety standards.

Collo was founded in 2017 after extensive scientific research into electromagnetic field measurement technology at the University of Tampere, Finland.