Since 1905, Satab, an independent family-owned company, has been creating, weaving, braiding and knitting ribbons, braids, straps, cords... Specializing in narrow textiles, the company presented two printing techniques at the Luxe Pack trade show - held from September 30 to October 2, 2024 in Monaco: inkless printing and 3D printing.

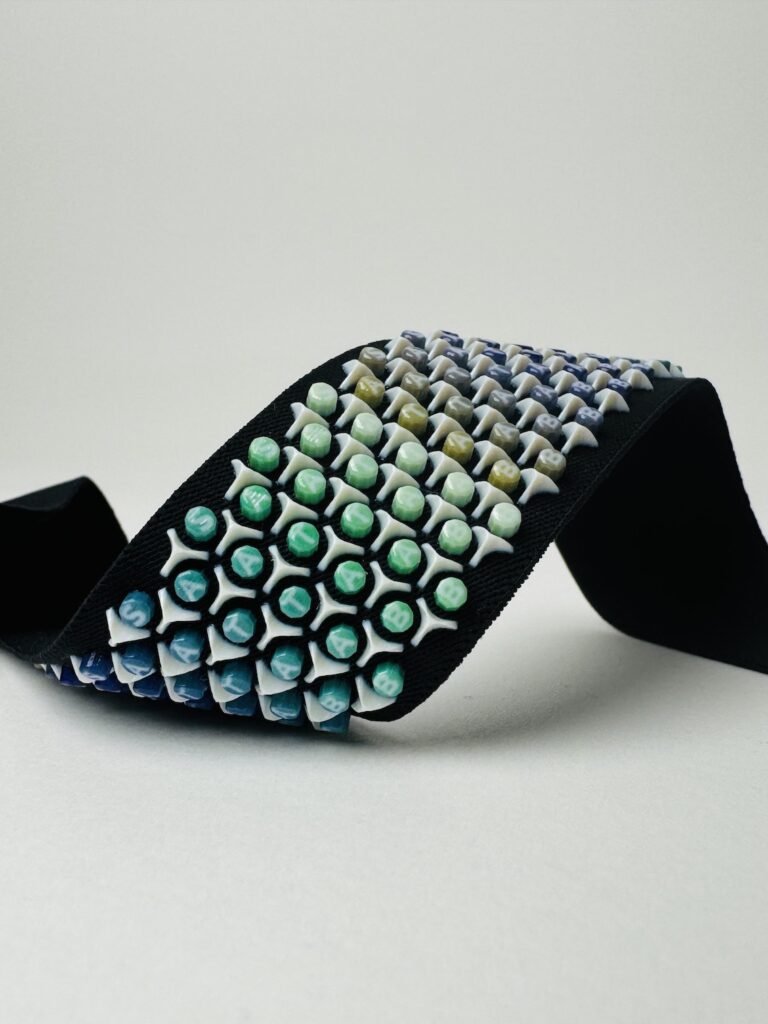

The Haute-Laure-based company unveiled its latest innovation at the show: 3D printing on narrow textiles. This makes it possible to create volume prints, up to a maximum height of 50 mm, on rigid or elastic ribbons.

Thanks to opaque or transparent resins and an almost unlimited color palette, Satab promises unprecedented design freedom. The 600,000 colors available, plus the Pantone range in matte and gloss finishes, make it possible to create unprecedented effects. With the ability to 3D print on a variety of materials and ribbon widths, this technology offers the possibility of creating unique colored volumetric patterns, and opens up a whole new world of possibilities for packaging, perfume caps, spirits bottles and jewelry cases.

With a view to protecting the environment, Satab has also added two new inkless printing processes to its printing expertise. Embossing, which consists of hot stamping, causes embossing and creates tone-on-tone designs on ribbons; color is replaced by relief.

Laser marking uses a beam of light to produce a durable mark on the textile surface; the color is "tattooed" onto the ribbon. These two printing processes require no water or ink, and enable ribbons to be personalized without impacting their ecological footprint.

For several years now, Satab has been developing an ever-expanding range of ribbons made from eco-responsible materials. This collection includes linen ribbons certified Masters of Linen, guaranteeing the traceability of premium linen grown in Europe, as well as ribbons in Tencel FSC, ecological and biodegradable fibers obtained from wood pulp, Gots cotton ribbons, paper yarns and GRS-certified fibers. The range's attractiveness is further enhanced by its inkless printing option.

Inkless printing processes represent the transition to packaging with a lower impact on the environment.