Printer Martinenq has selected references from Italian papermaker Fedrigoni, specialized in the creation and manufacture of top-of-the-range paper, for its packaging.

Since 2024, Martinenq has been innovating in the perfume segment, extending its expertise to packaging and offering products dedicated to fragrance discovery and cosmetics testing. For its new products, the printer has chosen two flagship Fedrigoni references.

Fedrigoni's Carte à Parfum range comprises uncoated, FSC-certified papers made from long fibers. It is available in five grammages (from 140 to 350 gr/m2). Martinenq chose this reference for its printability, resistance to humidity and perfect reproduction of olfactory notes.

"Considered a niche product when it was created 15 years ago, the Cartes à Parfum range has now become THE benchmark for brands and converters, thanks to its technical and aesthetic advantages. Our collaboration with Martinenq is a fine example of the partnership approach we value so highly".explains Céline Bertuzzi, Marketing Director of Fedrigoni Special Papers.

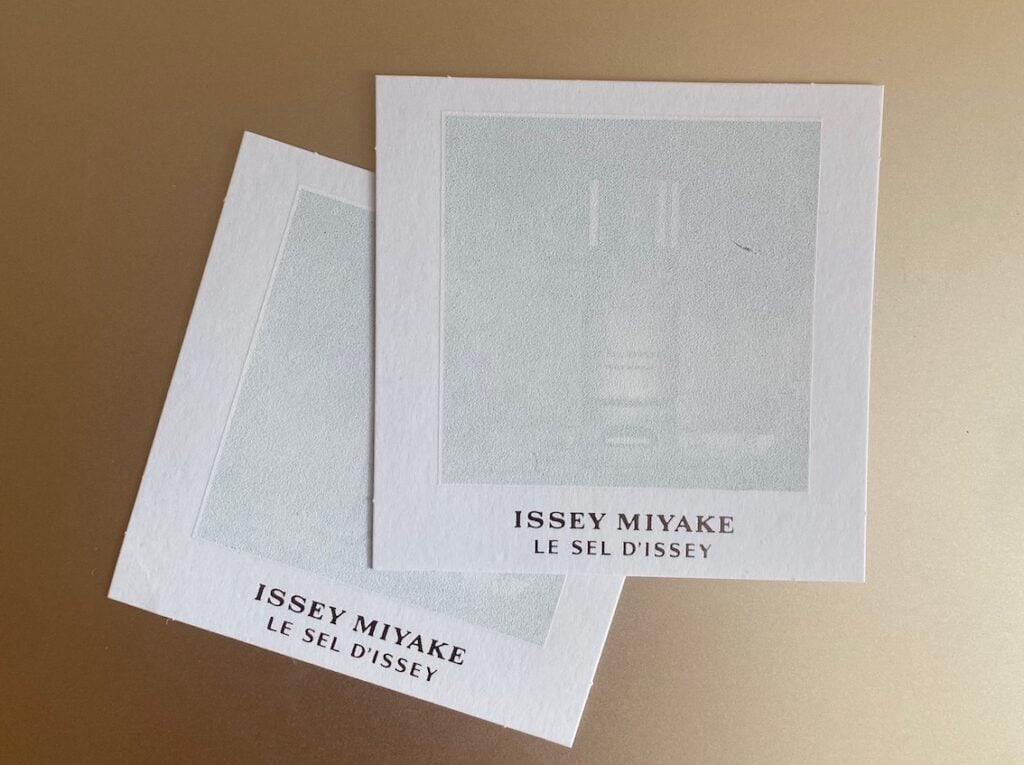

A "wow" 100 % blotter

Martinenq has chosen to apply a "hidden message" to the perfume card, using a "revealing" ink. Once printed, the image is then covered by a thin translucent layer applied in white silkscreen. Under the effect of vaporization, this film disappears, revealing the message (logo, motif, words...). The "wow" effect supports the marketing gesture and is renewed after drying. Shiseido adopted this concept to promote the launch of its perfume Sel d'Issey.

The magic of microencapsulation

Martinenq has also chosen the 300g Carte à Parfum to introduce brands to its microencapsulation process. The process relies on micro-cells that trap the juice. These are mixed with the ink before printing on all or part of the card, before releasing their fragrance by bursting when rubbed. With this technology, the fragrance can be preserved for perfect olfactory reproduction at any given moment.

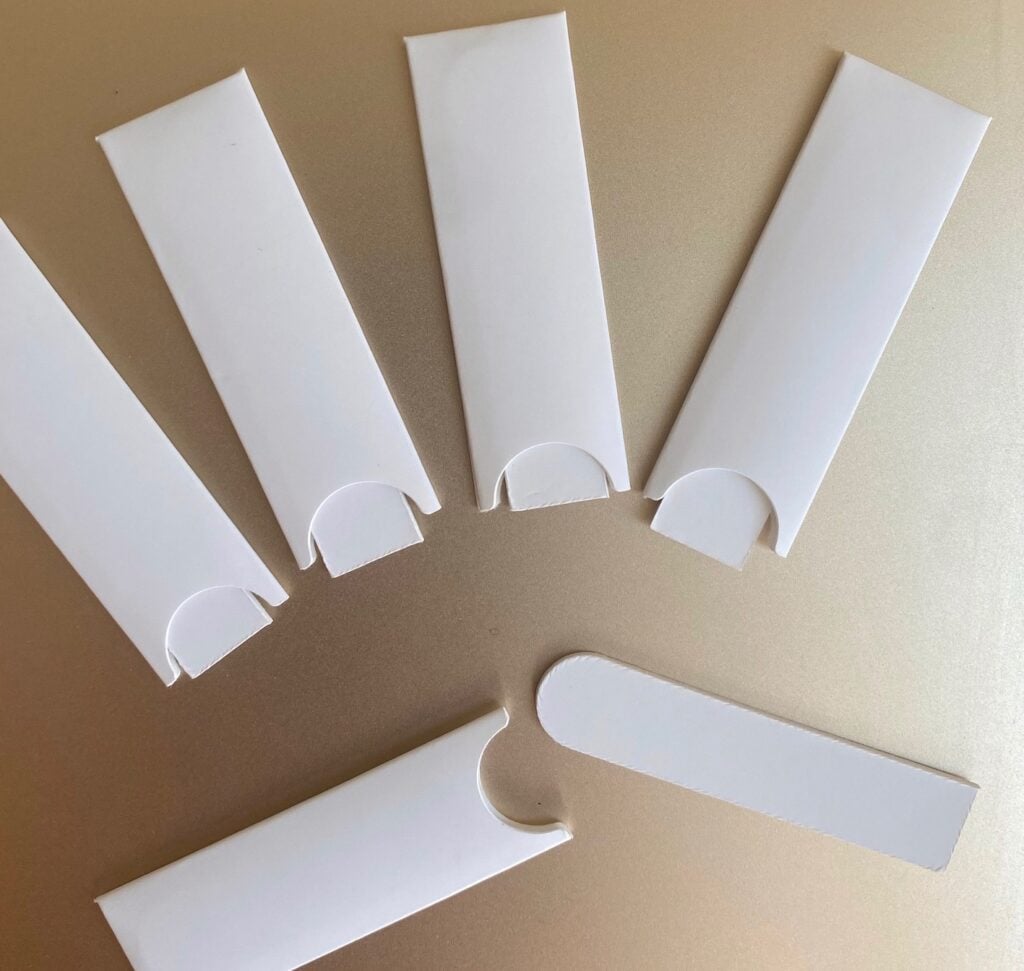

A card spatula

The Symbol Card reference is used for a plastic-free cardboard spatula. Ideal for testing cream at the point of sale, this test tool has been developed from Fedrigoni's Symbol Card FSC (582g) coated on both sides for a totally resistant and slippery surface, with no risk of wrinkling. It can be decorated at the top and even embossed. Martinenq offers it in a choice of delicate sheaths, also made from Symbol Card coated on one side (210 gr), so it can be decorated as required.