This collaboration, to launch a new event in Geneva, marks the latest expansion of Europe's leading network of events dedicated to packaging innovation.

Easyfairs, the world's leading event organizer, today announces the latest expansion of its international network of packaging events with a new partnership for Connect in Pharma, a new trade show aimed at driving innovation in the international packaging, medical device and pharmaceutical production markets.

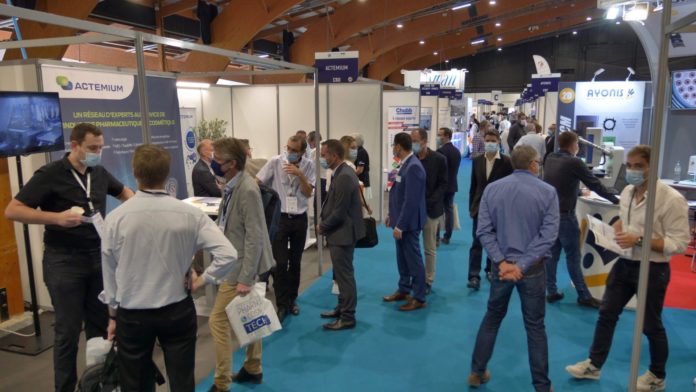

Connect in Pharma was initially created by MIND Exhibitions to provide a platform of excellence for pharmaceutical and biotechnology production, with a qualitative, enriching and user-friendly experiential approach. Connect in Pharma will bring together the international pharmaceutical market to define its future in one of the industry's leading international hubs, Geneva.

Dedicated to suppliers downstream of the pharmaceutical molecule and biotech products, it will focus on stimulating innovation and networking in four key areas: packaging, medical devices, subcontracting (CMO/CDMO) and production machinery and processes. It will attract suppliers in these markets, as well as partners in regional clusters and associations, to put them in touch with the innovation, R&D, production and procurement teams of pharmaceutical and biopharmaceutical companies.

In addition to exhibitors showcasing their innovations and new products, the event will feature a wide range of animations and conferences designed to inspire new connections, collaborations and innovations in the marketplace. An annual program of digital and face-to-face activities will support the event in its mission to catalyze and connect the community.

The partnership with MIND Exhibitions for the launch of Connect in Pharma builds on Easyfairs' existing and expanding network in the international packaging market. The group already organizes packaging events in 12 cities across 10 countries, covering all aspects of the packaging supply chain, including design, development, manufacturing and logistics.

Many of these events are already attracting audiences in the pharmaceutical market - including ADF&PCD and PLD Paris, which has more than tripled in size since Easyfairs acquired it in 2016. Easyfairs also organizes Maghreb Pharma, North Africa's leading trade show for the pharmaceutical industry. Based in Algiers, Maghreb Pharma connects the supply chain for production technologies and pharmaceutical formulations across the region and, as of this year, also welcomes new zones dedicated to packaging and cosmetics.

As a result, Connect in Pharma will benefit from the Group's existing expertise and relationships in the packaging market, as well as its proposed suite of tools and systems, to optimize the quantity and quality of connections and knowledge the event offers to buyers and suppliers in the community.

Event co-founder Jérôme Letu-Montois and members of the MIND Exhibitions team will remain active in the organization of the event alongside a dedicated Easyfairs team, ensuring the event's continuity and success.

Renan Joel, Divisional Director for Easyfairs Packaging Shows, comments: "Connect in Pharma is an exciting new show for a vital, dynamic and innovative international market. I can't wait to start working with the MIND Exhibitions team and the wider community to build a great event that will help drive innovation in the pharmaceutical sector."

Jérôme Letu-Montois, Co-Founder of Connect in Pharma, comments: "We are delighted to be working with Easyfairs to build this event and create a new hub for this community. Integrating the event into Easyfairs' existing network and structures will enable Connect in Pharma to establish itself more quickly, and will also offer our exhibitors and visitors additional services and technological tools for a better experience. Our team is very excited to start working with our new colleagues and the industry to make this happen."