Real-time monitoring and control of color throughout the production process requires compact, robust, process-oriented instruments. The Memosens Wave CKI50 process spectrometer designed by Endress+Hauser, specialists in the development of measuring instruments, meets these requirements. This eliminates the need to take samples and send them to the laboratory for analysis in order to release the batch.

For consumers, a consistent color is often a sign of product quality and recognition. When the color changes, they may assume that the product has changed too. However, everyday products made from natural ingredients and substances, which are appreciated by consumers, are strongly influenced by the natural effects of time and light, which affect the quality and color of the final product.

To meet consumer expectations, color is in most cases adjusted during production. When a wide variety of products are involved, many different colors quickly come together. This implies a need for reproducibility and control.

Greater production safety

In addition to color control, ensuring that the right product goes into the right container - a bottle, for example - is also essential. Measuring color can therefore be a means of control. It is used when changing products or cleaning piping. Color measurements can detect whether the line contains residues of a previous product or a new, pure product.

As a result, manufacturers will be able to monitor the color of the product in the pipe or tank in real time, enabling them to adjust the color as closely as possible to specifications, carry out on-line quality control before batch release, and monitor the quality of high value-added products.

Real-time measurements

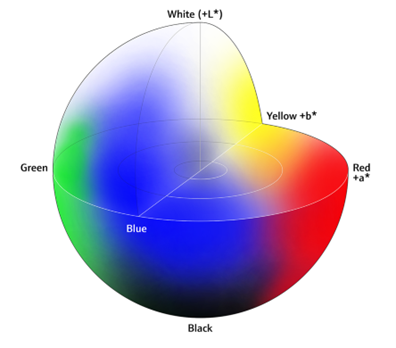

The Memosens Wave CKI50 process spectrometer measures color using visible spectroscopy. It scans the 380 nm to 830 nm wavelength range of the electromagnetic spectrum in real time, and displays the measured color in a normed space (a three-dimensional color space).

The four main benefits of this spectrometer are as follows: time savings in batch release, but also in detection and decision-making in response to non-conformity; reduced material losses in sorting phases, with instant and reliable detection of product change; simple commissioning thanks to Memosens technology - a technology introduced by Endress+Hauser in 2004 and continuously improved - and Endress+Hauser's Liquiline transmitter; and long-term reproducibility and reliability of color measurements, even in demanding process environments.

Compact and robust, the Memosens Wave CKI50 combines probe and spectrometer in a single device. Adaptation to different process conditions and simple integration enable on-line measurements under a wide range of industrial conditions.

The equipment incorporates a long-life halogen lamp and a module for separating and analyzing each wavelength individually.

Photo: Memosens Wave CKI50 spectrophotometer and Liquiline CM44P transmitter