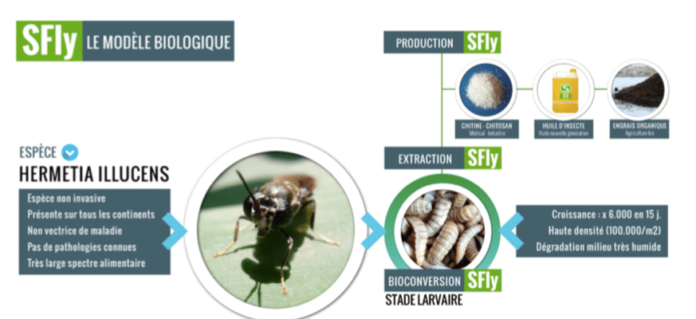

The Isère-based start-up has developed an original process using the Hermetia Illucens (Black Soldier Fly) to mass-produce chitosan, a high value-added product used in the medical, pharmaceutical, cosmetics, environmental and industrial sectors.

SFly, a start-up that has developed an innovative insect-chitin bioconversion model, has just successfully validated its integrated process for extracting the chitin making up the exoskeleton of the fly Hermetia Illucens, in an optimal way (environmental and financial footprint), and manufacturing a certified-quality chitosan.

Already used in numerous products (suture thread, artificial skin, anti-ageing cream, non-allergenic and anti-bacterial textile fiber, fungicide, fertilizer...), chitosan is a key resource with highly promising applications.

This first major step in the start-up's development has enabled it to complete the financing of the second phase of its strategic plan: setting up its pilot production unit on the Inspira platform at Salaise-sur-Sanne in Isère.

A stable, controlled process

SFly has developed a controlled process, ensuring traceability, repeatability and quality control throughout the manufacturing process. The project is the result of more than four years of proprietary research, and has benefited from private funding of 400 k€ and 200 k€ from the Bpifrance innovation fund. The aim is to develop a new French industrial production chain for insects, using high-performance chemical processes to manufacture medical- and cosmetology-grade chitin and chitosan.

Bio-resources for the future

These strategic products, for which global production is currently insufficient to meet industrial needs (known demand for chitin in 2017 was over 75,000 tonnes for 40,000 tonnes produced), are currently extracted from shrimp shells, mainly by Asian companies. Global demand for chitosan is growing fast (16% per year) due to its many applications, such as in water treatment, food and beverages, cosmetics, industry, biomedicine and pharmaceuticals, and agrochemicals. The global market for chitin derivatives is expected to reach $63 billion by 2021, according to a report by Global Industry Analysts Inc. (chitin and chitosan derivatives market report - 2015).

"The validation of our process represents a major milestone in our development, as well as being a source of great satisfaction. Every stage has been meticulously dissected and optimized: large-scale rearing of Hermetia Illucens larvae, control of larval feeding, fly reproduction, chemical chitin extraction process, chitosan production and waste recycling. Ensuring traceability and repeatability throughout the entire process, from input to finished product, is a first that sets us apart from current chitin/chitosan producers. We can now offer molecules that were previously inaccessible. Another advantage of our chitosan is its purity, which will enable us to produce 100 % of our production in pharmaceutical grade. The next steps will be our financing round and the construction of our pilot production unit," explains Philippe Crochard, co-founder of SFly.