To meet its customers' expectations in terms of aesthetics and creativity, Carestia has just commissioned its latest machine, promising an extra-fine cutting process and top-quality finishes.

A specialist in perfume discovery, Carestia stands out not only for its ability to work with very small-format products, but also for its experience in fine gilding, embossing and die-cutting processes.

Industrial challenge

Motivated by the ever-increasing demands of its customers, Carestia has succeeded in challenging the limits of traditional die-cutting to achieve exceptional finesse. Over time, the Grasse site has succeeded in optimizing the rendering of its die-cuts by adapting other types of tooling little used by the cardboard and commercial printing professions.

As proof, the 3D-cut blotter recently produced for Dior is the culmination of several months' development of this type of tooling.

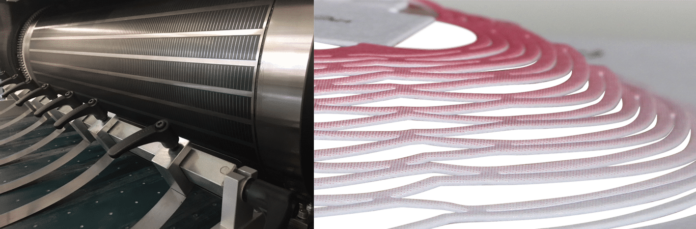

Today, Carestia is unveiling a brand-new machine. This machine offers a host of advantages, including low rejects, rapid set-up and execution, and adaptability to both small and large quantities. Its innovative die-cutting system enables original finishing of printed products such as blotters, folding cartons, envelopes, sample cards...

This machine enables Carestia to improve the fineness of cut-outs, as well as the rendering of large dry stamping areas such as reproductions of fabric wefts and other decorations.