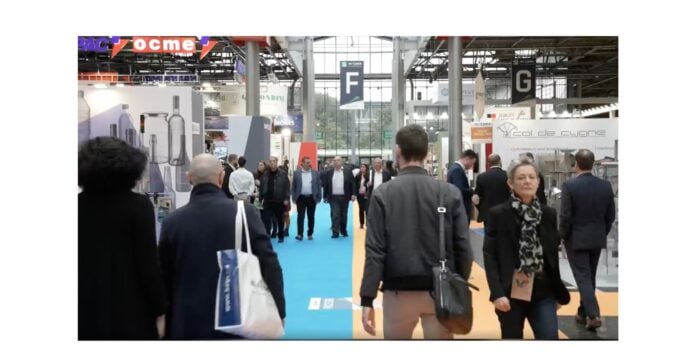

France's leading international trade show for the packaging industry, All4pack Emballage Paris will be held from November 4 to 7, 2024 at Paris Nord Villepinte. A flagship event, the show is positioned as a showcase for all innovations in the service of sustainability, performance and profitability. The aim is to help professionals meet the ecological challenges of today and tomorrow.

Featuring conferences, exhibition halls and business meetings, All4pack Emballage Paris revolves around packaging, processing, printing and logistics, covering packaging and machinery solutions for all industries (food, industrial goods, distribution and e-commerce, pharmaceuticals/health/cosmetics, luxury goods, takeaway).

An industry think tank

For its 2024 edition, the show intends to assert itself once again as a place for business, with the organization of business meetings between visitors and exhibitors, as well as delegations of top international buyers. It will also be a place of reflection and influence, a laboratory of ideas and innovation for all players and decision-makers in the packaging sector. To this end, the show has set up a "Pack Expert Committee", made up of 14 members from some of the most important international groups in their sectors (Citeo, Coca-Cola France, Fleury-Michon, Groupe Bel, L'Oréal, Lea Nature, Pierre Fabre, Procter & Gamble, Rémy Cointreau...), who meet to discuss their expectations as packaging-using industries, and enable the show to be anchored in the concrete concerns of the sector.

The show is also supported by numerous partners: Citeo, Carton ondulé de France (Cof), Conseil national de l'emballage (CNE), Elipso, Fédération nationale du bois (FNB), Geppia, Secimep... And, for the first time this year, the European Brand And Packaging Design Association (Epda) and the World Packaging Organisation (WPO).

Some 1,100 exhibitors and brands are expected, including 50 % internationals. Numerous companies such as Armando Alvarez, Atlanta Stretch, Beckhoff, Bfr System, Cama Group, Citeo, Competek, Domino, Fanuc, Fromm, Getra, Goglio, Ima Group, Ocme, Raja, Robopac, Sidel, Siemens, Soretrac, Yaskawa and Zalkin have already confirmed their attendance.

A rich event

All4pack Emballage Paris 2024 will be held in Halls 4 and 5 of the Parc des Expositions de Paris Nord Villepinte. This layout will enable the 50,000 trade visitors expected to attend (including 35 % international visitors) to be distributed evenly, thanks in particular to entertainment hubs located in each hall.

Hall 4 will bring together exhibitors offering multi-industry process & packaging machinery/marking, coding and printing of packaging, converting, labels, and will host the new All4pack Circularity area, a zone dedicated to circularity, bringing together innovative startups and other players involved in the transition process.

All4pack Circularity aims to bring together all those involved in eco-design, recycling, reuse and environmental footprint reduction, by showcasing innovative solutions for companies using packaging. In this area, visitors will find the start-up village and an agora dedicated to exhibitors' presentations.

Hall 5 will house the processing, logistics and packaging worlds, as well as the conference area and the All4pack Innovations zone.

The All4pack Innovations area, co-designed this year with the European Brand & Packaging Design Association, will showcase the winners of the All4pack Innovation Awards 2024. This space will explore the latest trends and offer an opportunity to discover, through the competition's winning exhibitors, the latest innovations in the sectors presented at the show. It will also showcase the winners of the show's partner competitions: L'Oscar de l'emballage, NVC Gouden Noot, SIAL Innovations, Emballé 5.0. A new feature: an exhibition of innovative packaging sourced and analysed by the EPDA.

In addition, the "Pack Innovation Tour" and "Pack Machine Tour" guided tours will unveil innovative solutions selected by experts: meetings with exhibitors, machines in operation, discovery of cutting-edge packaging.

Some 27 high-level conferences will be held in the All4pack Conferences area. These will be linked to the major issues facing the packaging-using industries: environmental, legislative, technological and also societal, with the new habits of both French and international consumers.

Chantal de Lamotte, show manager

With her extensive knowledge of event management, Chantal de Lamotte has taken over the management of All4pack Emballage Paris and Solutrans (transport solutions trade show), while retaining the management of Djazagro (food production trade show). She is supported by a close-knit team committed to the development and international influence of these events.

Chantal de Lamotte reports to Laurent Noël, Comexposium Division Managing Director.