Positive Plastics offers a unique kit of various resins and plastic compounds that enable products to transition towards sustainability and circularity. Roctool engineering focuses on the " heat & cool "In this way, we can improve the quality and processing of recycled plastics.

Positive Plastics aims to give designers, engineers and product managers a more positive vision of plastics. Since the launch of its first kit at Fakuma 2021, Positive Plastics has offered an updated version every year, with ever more innovative resins. These plastics are suitable for injection molding in the manufacture of luxury products such as packaging, consumer electronics, household appliances, sporting goods, automotive accessories and more.

Roctool and Positive Plastics sign four-hands kit

The Positive Plastics team, which is constantly striving to offer new circular solutions, was delighted with Roctool's initiative to create a combined kit for the new edition.

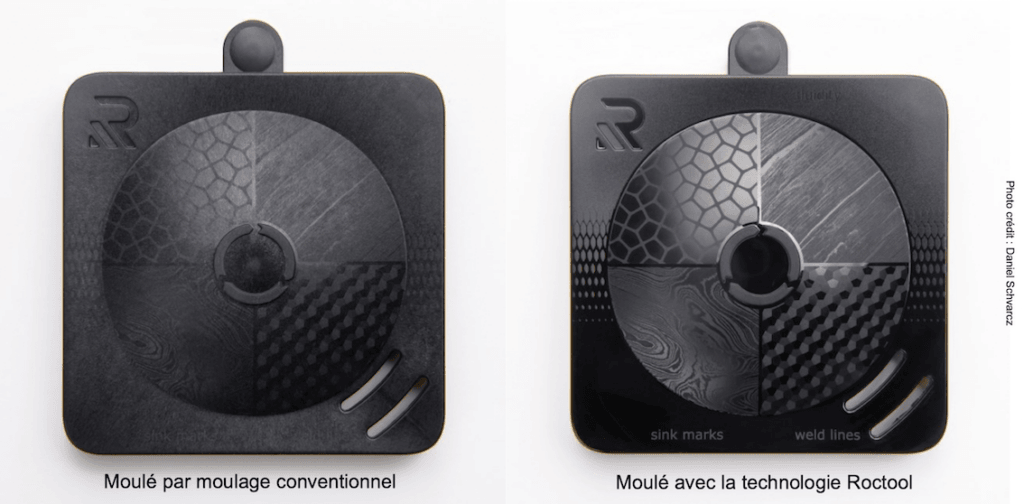

Mathieu Boulanger, CEO of Roctool, said: "I love Positive Plastics' projects. This kit is a great tool for any designer looking to create more sustainable products. But I firmly believe that the material is not the only parameter to consider. It's up to us to see how we can improve the perceived quality of these materials. How can we improve the look and feel of recycled materials without surface decoration? We lacked this perspective. So I proposed to Positive Plastics that we collaborate and explore this avenue."

Markus Paloheimo, co-founder of Positive Plastics, and the Roctool team have designed a new device to showcase the different qualities, textures and mechanical properties.

The Pernoud Group modified the mold and Oerlikon Balzers supplied the hot runners.

The Positive Surfaces kit features 100 % post-consumer, mechanically recycled materials: PP, PET, ABS, PC/ABS and ABS with glass fiber.

"We're delighted to provide designers with additional know-how and tools to create aesthetically pleasing, circular products.says Efrat Friedland, co-founder of Positive Plastics. Roctool molding technology has proven its worth. It enables the creation of advanced surfaces, ranging from matt to high-gloss finishes. In addition to the aesthetic benefits, brands also have the opportunity to eliminate secondary operations and thus reduce production costs. The induction process improves the whole process, eliminating defects, improving flow and, depending on resin quality, reducing cycle time. This is a real opportunity to highlight recyclates and encourage their adoption by consumers."

The official launch of the Positive Surfaces and Positive Plastics kits is currently taking place at the Fakuma trade show, which runs from October 17 to 21 in Friedrichshafen, Germany. They will be presented on the stands of Sabic, Mocom, Poracom and Group Pernoud.

Positive Plastics will be sending out a free kit to one hundred brands and design agencies, as it has done with previous kits, to encourage the creation of new products.

The latest kits will soon be available for purchase online.

Photos : © Daniel Schvarcz