In 2002, when B.Pack, France's last remaining cardboard manufacturer, was looking for new investors, Wauters was the obvious choice. Although it had met with a number of potential investors, B.Pack identified with Wauters' values.

For their part, Wauters, who had never had any intention of growing the company by acquisition, met B.Pack at the suggestion of one of their customers.

It was a shared vision of the business that prompted the takeover of B.Pack :

- a family spirit

- proximity

- French manufacturing

- the same attention to detail and the same high standards in every project.

Wauters (at Villebon-sur-Yvette, Essonne) and B.Pack (at Couches, Saône-et-Loire) are equally committed to investment and innovation. This joint research has led to the development of new solutions such as bio-sourced inks and wafer paint.

Both sites have always been equipped with state-of-the-art technology, and in an equitable way: after the installation of a new offset press in 2020 on the Couches site, a new press is also being installed on the Villebon site.

Complementary equipment

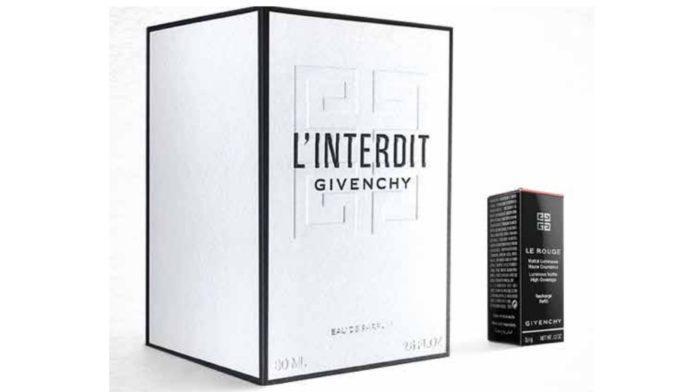

The complementary nature of the facilities at the two sites has enabled us to meet the different demands of the luxury goods industry.

Small series and small formats are produced at Couches, while large series and large formats are produced at Villebon. This flexibility in terms of production quantities enables the Wauters Group to accompany the product throughout its life cycle:

- from launch with large quantities to the maturity phase, when quantities decrease,

- and vice versa, from small series at B.Pack to large series at Wauters when market demand is stronger.

Format flexibility also enables us to meet the different demands of brands for the same product line: fragrance cases, by-products, samples, make-up, skincare...

Sharing know-how

Whether production is carried out at Wauters or at B.Pack, the Group guarantees the same quality criteria and the same end result.

Internal guarantors work on both sites to pass on technical elements and methodology, and to train teams in the same way.

In addition, the Group has invested in similar tools for both sites:

- an Epson proofing printer for color output

- Measure Color, which measures spectrocolorimetry (quantity of ink printed on the sheet) and measures a color in relation to a target (chromatic circle). This makes it possible to define with a customer the authorized Delta E, i.e. the possible maneuvering range around the target color. This very precise data serves as a common reference between the customer, the Villebon site and the Couches site.

Reuse of tools, transfer of documents and in-house team training: sharing know-how between the two sites also saves time and money.