Watson-Marlow Fluid Technology Solutions, a specialist in pumps and fluid management solutions, and Mettler Toledo, a major global player in precision instrumentation and services, offer a customized dosing solution for biotechnology products.

A French chemical and biotechnology manufacturer was looking for a precision dosing solution for packaging a biotechnology fluid in 125 ml vials and for batches of 70 to 180 vials, with a filling accuracy of ± 0.5 % controlled by a balance.

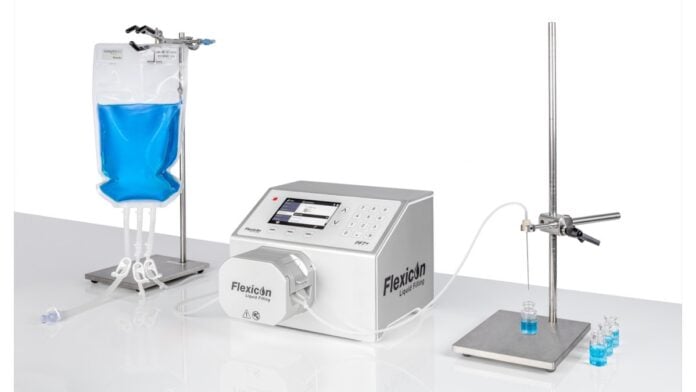

To meet these needs, Watson Marlow offers a Flexicon (WMTFS) precision peristaltic pump, the PF7+. This 21 CFR Part 11-compliant pump has been developed for critical aseptic final filling applications. It is characterized by its ability to deliver waste-free batches. The PF7+ is designed to be coupled with a high-precision balance for dynamic recalibration with pump control. Rapid dosing, even with manual filling, is possible with reproducible filling accuracy in line with demand.

The PF7+ advanced filling kit includes a Mettler Toledo analytical balance with an air flow screen and an integrated, adjustable nozzle holder.

A special set-up

In the case of the pharmaceutical laboratory, an existing assembly already included a support and a filter.

"Our customer needed a bespoke solution that did not include a weighing cage, with a larger weighing range than that offered by the PF7+ filling kit scale, and with less accuracy than those generally required in the applications in which our pump is deployed. In particular, it required the use of a final filter downstream of dosing, to guarantee the integrity of their product, and filling with a continuous tube. These conditions, the filter and the continuous tube, greatly disrupted filling accuracy performance, which had to be maintained at 0.5 %. In addition, the customer did not want the system to be computer-controlled.explains Anaïs Soccio-Koestel, Sales Engineer at Watson Marlow France.

A customized filling solution, coupled with a scale with a larger capacity than the one initially proposed, and without a windscreen, was therefore required. Mettler Toledo's New Classic range of precision scales met this need.

A tailor-made solution that extends PF7+ applications

Watson Marlow and Mettler Toledo have developed a tailor-made advanced filling kit that includes a PF7+ pump and a compatible Mettler Toledo scale from the ML range. With a range of 10-2, this scale is ideally suited to the application.

The PF7+ pump is fed by a 50-liter bag containing 6 liters of product. The bag already contains a continuous tube with an internal diameter of 6.35 mm and a thickness of 2.38 mm.

A single-use sartopore 0.2 µm filter is positioned on a holding rack which incorporates a filtration system before the product is injected into the vial. Each vial is placed on the balance to validate its weight.

Anaïs Soccio-Koestel adds: "Our customer requested that the traceability of each bottle be controlled by weight. In this case, and this is what makes our solution so interesting, the scale communicates directly with the pump: it determines the right dose and prevents the filter from interfering with the dosage. It is also connected to a printer, which delivers a printout of the weight of each bottle.

This new kit, consisting of a PF7+ peristaltic pump coupled with a Mettler ML balance, extends the pump's possible applications. It can be used for small-batch dosing with accuracy requirements in excess of 0.5%, applications requiring continuous control, continuous tube use and special fixtures.