In an industrial context where precision and reliability are paramount, Gericke presents its new range of deagglomerators designed to optimize production processes while ensuring easy maintenance.

Gericke, specialist in powder handling systems, introduces a major innovation with its new series of deagglomerators. Essential for restoring the particle size of powdered products after storage, these devices play a key role in maintaining the integrity of the final product.

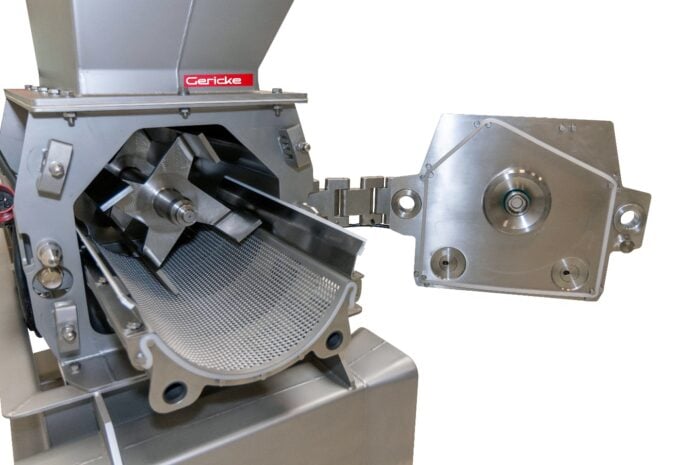

Designed with efficiency and safety in mind, these machines feature a four-blade rotor and a modular perforated screen with openings ranging from 2 to 25 mm. This configuration enables a wide range of products to be processed without generating undesirable fine particles.

A notable feature of these machines is their ease of maintenance. With a front door and a rail-mounted rotor/motor assembly, operators can easily access internal components for quick checks and cleaning, minimizing interruptions to the production cycle.

What's more, this equipment includes metal-to-metal contact detection, an essential function for preventing damage and contamination. Not only do these safety measures protect the equipment, they also ensure compliance with the most stringent safety regulations.

Available in stainless steel or painted steel, Gericke deagglomerators meet the requirements of the Atex directive, with versions adapted to hazardous areas. What's more, each model can be tested in a dedicated test room to demonstrate its efficiency before integration into customers' production lines.