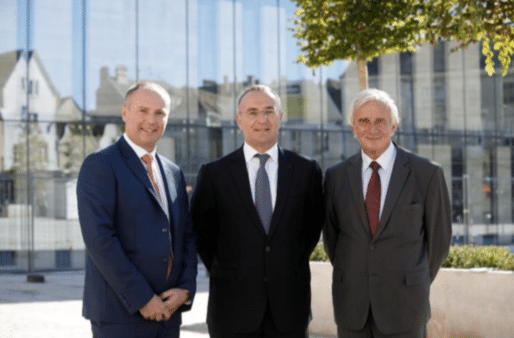

With a wealth of experience in innovation and research, the 43-year-old chemical engineer succeeds Jean-Luc Ansel, the outgoing Managing Director and founder of Cosmetic Valley.

On the proposal of its chairman Marc-Antoine Jamet (LVMH), the Cosmetic Valley board of directors, meeting on October 5, 2018, voted unanimously to appoint Christophe Masson as head of the competitiveness cluster, where he succeeds Jean-Luc Ansel, who had been its first managing director and, alongside Jean-Paul Guerlain, its founder.

Trained as an engineer (Chimie ParisTech, 1998), PhD in organic and bio-organic chemistry (Sorbonne University, 2001), co-author of 10 publications and 5 international patents, Christophe Masson (43, married, 3 children) has been in charge of Cosmetic Valley's Research and Innovation strategy since 2009. He has been the cluster's Deputy Director for the past year, and will now take over as its General Manager.

Marc-Antoine Jamet has asked Jean-Luc Ansel to become Executive Vice President and to oversee, on behalf of the Board of Directors, the cluster's international dimension and the Maison de la Cosmétique, which is to be built in Chartres. The former Managing Director will also be working on a project in which he is a recognized specialist: Cosmetopoeia.

Marc-Antoine Jamet, President of Cosmetic Valley: "This is a well-prepared, harmonious and logical transition. That's how I wanted it. Of course, I'd like to thank Jean-Luc Ansel for all he has done for our companies and their success. Today, he leaves the helm of a cluster that ranks first among its French counterparts in terms of the number of its members. It is thanks to him, and to the extremely efficient, modern, multi-purpose tool he has developed to serve the French economy and the industry, that we have achieved this result. We owe it all to him. I have personally enjoyed working with him for the past seven years. I'm delighted that this collaboration, in another form, will continue. I am also delighted to see the arrival of Christophe Masson, whose extreme competence, lucidity and hard work I have noted. He knows the roadmap that the Board of Directors has given him. At the head of our team, he will have to embody the cluster's modernity, keep moving forward, fortify our achievements, diversify our activities, establish our leadership and win new victories. I have every confidence in him. He has the energy and the talent.

Christophe Masson, Managing Director of the competitiveness cluster: "I'm deeply honored both by the trust placed in me and by the fact that I'm taking over from Jean-Luc Ansel. Over the past 25 years, together with our teams and a network of committed players, he has created and developed a formidable tool for economic development and attractiveness. My appointment brings two words to mind: continuity and ambition. The cluster has its roots and values, and I'm determined to consolidate them. But more than ever, Cosmetic Valley must innovate in its actions and services for the industry and for the regions. Federating the French industry, driving a European dynamic, developing our self-financing capacity... These are the many challenges we have to meet for our industry and for made in France".

Jean-Luc Ansel, Vice-President, International, Maison de la Cosmétique and Cosmétopée. "It's a smooth transition that I've been preparing for a long time. It is now effective. After having created and developed Cosmetic Valley to make it a success story and a spearhead for the perfumery and cosmetics industry and for Made in France, I am particularly pleased that the Board of Directors has entrusted the management of our cluster to Christophe Masson. He has my confidence and my friendship. For my part, I'm delighted to continue to support Cosmetic Valley, as suggested by its President, as Executive Vice-President. In particular, I'll be keeping a close eye on the Cosmétopée project, which opens up great prospects for territories with high levels of biodiversity."