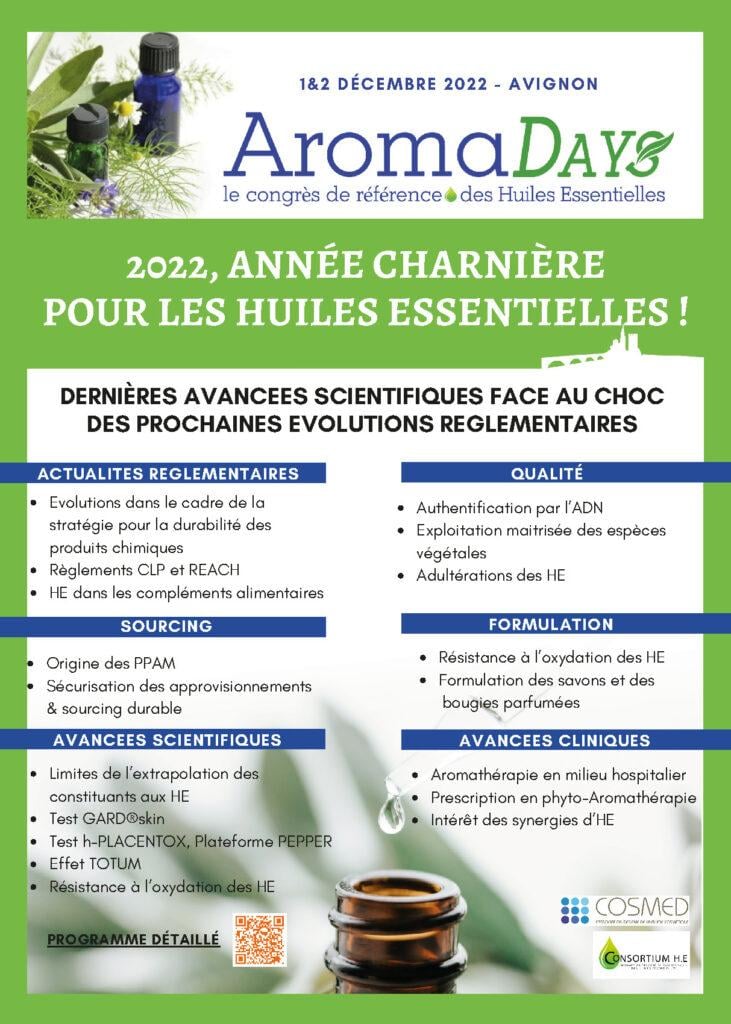

After months of exploring new ideas, testing new materials and pushing the creative boundaries, the innovative new designs developed as part of the Make a Mark creative platform were unveiled on October 3 at the Luxe Pack Monaco .

Now in its second year, Make a Mark is led by Estal, Avery Dennison and Kurz and aims to accelerate innovation and sustainable solutions in luxury packaging design.

Guided by the overarching principle of "progressive design at the intersection of sustainability, luxury and innovation", twenty of the world's leading designers were invited to reinvent the future of luxury packaging in the Beverage, Wine & Spirits and Beauty & Fragrance categories.

Designers had access to the latest industry developments and packaging technologies, and were encouraged to think without cost or technological constraints to push their creativity further and break new ground in packaging innovation. Ideas were transformed into physical prototypes using glass from Estal, label materials from Avery Dennison and printing tools and embellishments from the Kurz Group. They were presented at Luxe Pack Monaco and are the subject of a special digital edition designed to inspire the global design community.

This year's designs are varied, with new concepts, textures and materials explored. Designers have not only pushed back expectations with bold innovations and designs, but have even challenged existing business models. Here are just a few of these superb designs:

– Officina Graficafrom Italy, chose water scarcity as its central theme. Believing that everyone has the right to clean drinking water, regardless of gender, race, religion, income or social class, the team drew inspiration from Estal Rude's collection, a selection of customized bottles in recycled Wild Glass 100%. The result is an exquisite design with flowing water on the outside and the brand's manifesto inside the bottle.

- The French language Partisan of Sense has created a playful range of cocktails to appeal to the tribes of Generation Z. The playfulness is expressed through feelings of variation, diversity and generosity, with a design exploring volumes, colors and textures. The glass plays on different colors and textures, but it's the Avery Dennison label that ties the layers together. Hot stamping with Kurz products expresses the brand's bright, high-end look.

– 56 Mar Design StudioIn designing its perfume bottles, the Dubai-based company has drawn inspiration from Pharaonic culture. The bottle is shaped like a falcon, the sacred animal of Horus, with a cap in the design of the Tutankhamen statue. The hieroglyphs are adorned with gold finishes, while Avery Dennison's Fasson Bright Foil Gold, a gold-tone material, is used to highlight the richness of Egyptian culture.

In a joint statement issued on behalf of Estal, Avery Dennison and Kurz, Vladimir Tyulpin, Head of Avery Dennison's Premium Market Segment said: "We asked our designers to let their imaginations run wild and create the unexpected, and that's exactly what they delivered. This year's concepts invite us all to reinvent what's possible in packaging design and the positive messages it can convey. We hope this will start a global conversation around dynamic, bold and creative new ideas. "

Officina Grafica's founders and creative directors, Vincenzo Macarrone and Tommaso Pecchioli, talked about their work and how they approached the Make a Mark project: "For over 15 years, we've loved dressing up wine bottles. This year, with the Manifesto project, we wanted to get an important message across to everyone, and leave an indelible mark on social communication applied to design."

Other designers involved in Make a Mark include:

43'oz design studioRepublic of Moldova: driven by the desire to transcend time and leave a lasting mark on the world, the team created a wine so ancient that it has become a museum piece.

Aktiva Brand Experience DesignSpain: Vannity is a fragrance concept that represents us physically, emotionally and virtually.

Apartment103France: "Saulvage" is a concept for spirits about climate catastrophes. Each variant features a piece of wood damaged by fire, raising awareness of the challenges facing humanity.

Black Eye ProjectUK: the phrase "What's your poison?" is the inspiration behind this concept, which draws on Victorian aesthetics and the eerie world of vintage poison bottles.

Black Squid DesignAustralia: The "Floater", traditionally a meat pie floating in pea soup and eaten with a spoon, is recreated in this design concept.

Bullet Inc.Japan: The city of Tokyo and its melting pot of cultures and values is the inspiration behind this bottle of sake.

FlovPoland: Happiness, the joy of bubbles and childhood memories are evoked by "Vivané", a name that combines the words "viva" meaning "to live" and "né" meaning "born" - a design vision that praises life.

forceMajeureUSA: A fragrance focused on a lasting solution for self-expression. The result is a ritual of filling and spraying.

Lonsdale, France: This concept is based on the vetiver plant and its noble heritage, and aims to challenge the perfume industry and create a new perception of luxury.

Maba, Spain: Nan Madol, an organic and unexplained vodka, tells the story of a small island in an enclave of paradise.

Morillas, Spain: a bottle design strongly linked to the interstellar environment, reflecting the future of spirits.

O,Nice! Design StudioItaly: For a third of humanity, drinking water is already considered a luxury. This project is a 50 cl bottle filled with running water, designed as premium packaging to show just how precious water really is.

Popular Packaging GmbHGermany: for this bottle of traditional German gin, the studio created an abstract version of a journey through a German garden, reflecting the fact that every gin is a journey of smells, essences and tastes.

Sociedad AnónimaMexico: the archaeological expressions of Mesoamerica have inspired Mesoamerican rum. This project focuses on the product's geographical and cultural origins, without resorting to stereotypes.

Sure B randesignArgentina: Gintography (Gin + Typographic) pays tribute to the first printing system, the movable type press created by Gutenberg in 1440.

ThinkBoldStudioPortugal: Cognac Garnier evokes the golden age of the Beaux-Arts and is inspired by the luxury and opulence of Monte Carlo's casino and opera house.

Zweischneider GmbH & Co. Co. KG, Germany: A design to reflect the changing wine industry and how climatic influences impact culture. This concept makes the DNA of each vintage, including the number of bottles and alcohol content, tangible for the consumer.