Toly, a specialist in the manufacture of cosmetics packaging, has adopted Scortex's Spark, an automated quality inspection solution based on artificial intelligence, for its production lines. In use on three production lines, this technology aims to reduce scrap rates and improve product quality. Interview with Olaf Zahra, Technical and Sustainability Manager at Toly. Interview by Scortex.

Can you introduce us to Toly?

Olaf Zahra: Toly is a manufacturer and supplier in the cosmetics industry. We manufacture packaging for skin care, colored products, perfumes and other areas of beauty.

What was your quality control challenge?

Olaf Zahra: Cosmetic packaging often has complex decorations, some of which are very fine. If we rely solely on operator control, it's sometimes impossible to detect all the defects. We needed an automated system to perform 100% quality control on the products we manufacture.

What were your quality control objectives?

Olaf Zahra: Our main objective is linked to the fact that some of the very fine texts inscribed on our products are legally binding, and because they are so fine, anomalies can easily pass through quality control processes undetected. Implementing a system that detects the problem immediately can reduce rejects and enable us to aim for a scrap rate of less than 1%, even on very fine decoration.

What were the results and benefits of deploying Spark?

Olaf Zahra: We've used vision systems before, but they were always very complicated to configure. Learning the system always took hours, days, sometimes weeks. The biggest advantage we've found with the Spark system is the ease of configuration. We can go from inspecting one decoration to another in a matter of minutes, an hour at most, rather than days.

Sometimes it only takes a few minutes for the operator to realize that product quality has changed. But in the space of a minute, we're already processing 50 to 60 parts, and every minute that passes represents significant rejects. Detecting the problem immediately, stopping the process and making adjustments, gives you a considerable advantage in terms of reject rate reduction.

Have you achieved your quality objectives with Spark?

Olaf Zahra: Absolutely. As I said earlier, the system's ease of use is the biggest advantage. And the investment more than pays for itself in reduced rejects and scrap rates.

Do you plan to deploy Spark on other production lines?

Olaf Zahra: Yes, we installed our first Spark kit about 18 months ago. We have 3 in total, and we plan to deploy them until we cover all our production processes with decoration. We'd like to try out the system on processes other than decoration too.

With the adoption of Spark, Toly has taken an important step towards automating the quality control of its cosmetics packaging. This technology has helped reduce reject rates and improve product quality. The results obtained have led Toly to envisage the deployment of Spark on other production sites, marking a significant step forward in their quest for performance and efficiency.

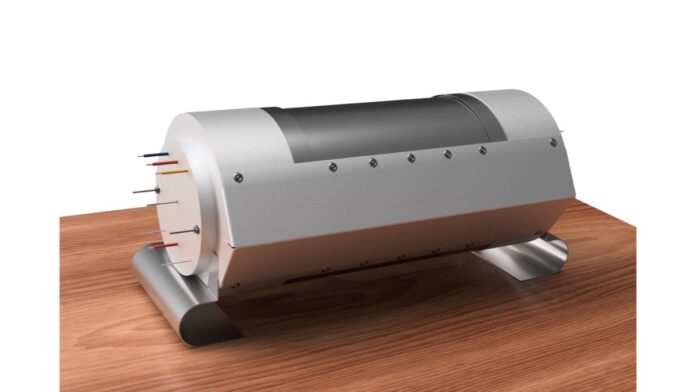

Spark, developed and fully assembled by Scortex in France, is an AI-powered automated quality inspection solution that offers a fast, easy-to-deploy approach without costly expertise. These are considerable advantages for production sites seeking to make the transition from manual to automated quality inspection, or to optimize their existing quality control processes, with the aim of achieving high-performance quality control, controlling the cost of quality and production on a larger scale, and reducing customer complaints.