In October 2018, Albéa joined the Ellen Mac Arthur Foundation's New Plastics Economy Global Commitment alongside L'Oréal, Unilever and other companies, pledging to make 100 % of its packaging recyclable, reusable and use 10 % of recycled plastic by 2025 - whether flexible tubes or rigid plastic cosmetics packaging. Three years on, while the acceleration is clear for tubes, the transformation process is more complex for rigid plastic packaging. This means above all selecting materials and optimizing decoration, integrating mechanical and chemical PCR (Post-consumer Recycled) and bioplastics, and reducing the overall use of plastics - major challenges that require far-reaching transformations.

Rigid plastic beauty packaging covers a wide range of products and technologies: lipstick cases and mechanisms, mascara bottles and brushes, skin care jars and bottles, perfume caps, powder compacts, compacts and many more. Some models are custom-made, others are standard designs. Since most of them are small and mix several materials, they are rarely recyclable, let alone recycled.

However, suppliers such as Albéa as well as leading cosmetics brands have committed to making all their packaging recyclable or reusable by 2025 - not just their standard tubes or bottles, where innovation is spectacular, but also their more complex make-up and skincare packaging, where transformation is less rapid.

The transformation of rigid packaging for cosmetics products therefore requires the mobilization of rare technical expertise, in the service of a very clear roadmap. This involves exploring new materials, notably PCR post-consumer recycled resins and bioplastics, adapting injection and decoration processes, and reducing overall material use. It's also about launching new responsible generic solutions and collaborating with customers on revolutionary customized products via our offer of technically recyclable solutions. Innovation in materials is essential here.

Our priorities are to find alternatives to resins that are not recycled or for which regulations are changing (such as the widely-used styrenics), focusing on the trio of PP, PE and PET, to aim for single-material packaging, even when it is multi-component, and to accelerate the use of post-consumer recycled (PCR) or bio-sourced resins.

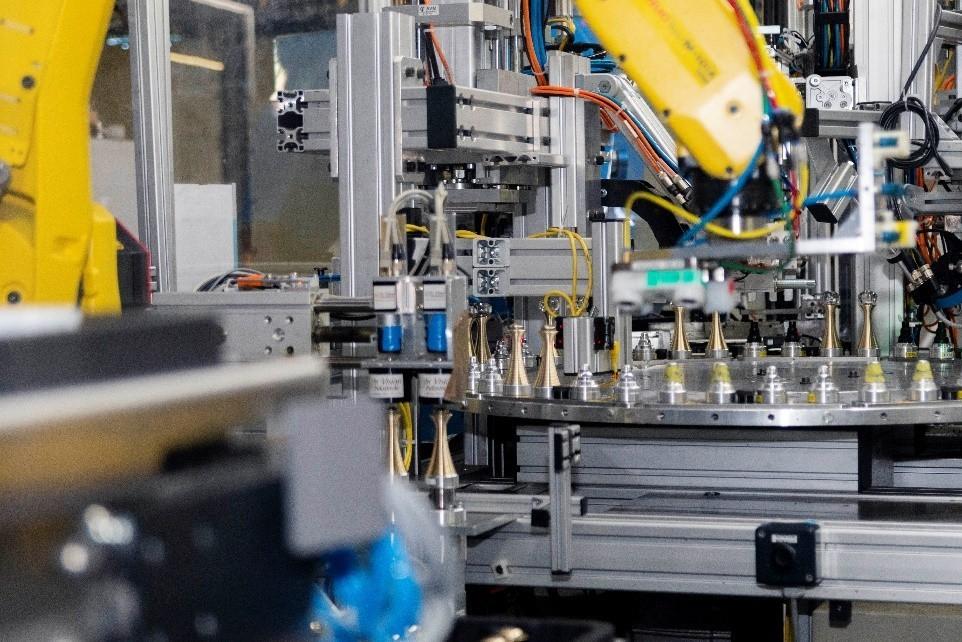

Our 14 industrial sites for rigid cosmetic packaging are now organized into a global network of injection experts, sharing best practices, ideas, successes and failures, as well as new sources of supply.

They are making progress in the field of chemical PCR, notably using coPET (Copolyester) for an aesthetic finish similar to virgin plastic, as well as in mechanical PCR with r-PET (recycled PET) for the manufacture of high-quality packaging. Today, 4 of our sites are ISCC (International Sustainability & Carbon certification, or mass balance) certified - 3 sites in China, and Simandre in France, our center of excellence for high-end care packaging.

Bertrand de la Tour, VP Marketing & Innovation Albéa CRP (Cosmetic Rigid Packaging), explains: " As brands accelerate the transformation of their standard tubes and bottles, let's kick-start the transformation of their more complex and strategic fragrance, skincare and make-up packaging. We position ourselves as expert and active advisors to all customers aiming to transition their current packaging portfolio, whether through material change or plastic reduction, bespoke product developments or via our offer of technically recyclable or recycled material solutions designed by our marketing teams.. "

Although there's still a long way to go, the transformation process is well underway, and Albéa's teams are working tirelessly alongside beauty brands to find responsible solutions.

"Visit us at LuxePack Monaco, hall Diaghilev, Stand DE07 "

Read more : www.albea-group.com